Agricultural and food industries face some of the most stringent waste management regulations in history. Yet, even with significant compliance efforts, excessive nutrient discharges still fuel toxic algal blooms, driving serious environmental and human health risks and causing economic losses across water-related industries, real estate markets, and local communities. The demand for effective, scalable nutrient recovery solutions is urgent.

According to the USDA, U.S. livestock and poultry operations generate more than 1.4 billion tons of manure annually . On top of this, the nation’s food and beverage sector adds tens of millions of tons of nutrient-rich food waste each year, much of it from manufacturing and processing facilities. Industry-wide estimates indicate that the industrial food system accounts for nearly 40% of total U.S. food waste, creating substantial pressure on land, water, and waste management infrastructure. These combined waste streams are often applied to farmland in excess of crop nutrient needs, driving runoff and water quality degradation.

The impact is widespread: from Chesapeake Bay in Maryland, to the Great Lakes spanning Michigan, Ohio, New York, and Ontario, to Lake Champlain bordered by Vermont, New York, and Quebec, and southward to Florida’s nutrient-polluted waterways, including Lake Okeechobee and coastal estuaries that regularly experience toxic blooms. Further downstream, nutrient inflows contribute to the large seasonal “dead zone” in the Gulf of Mexico.

The EPA reports that nutrient pollution has triggered harmful algal blooms in all 50 states and has contributed to more than 166 documented “dead zones” in U.S. waters , where aquatic life cannot survive. These ecosystems represent not only critical natural resources but also key economic engines for fisheries, tourism, property values, and regional industries, all of which are under increasing stress from unmanaged nutrient pollution.

This water pollution also drives up drinking water treatment costs and creates financial risks for both communities and producers. Farmers can spend tens of thousands of dollars annually on compliance with environmental regulations, and proposed policies such as the U.S. Farm System Reform Act envision penalties of up to $10,000 per violation per day for large operations. Together, these pressures highlight the need for practical, scalable technologies that prevent nutrients from becoming pollutants in the first place.

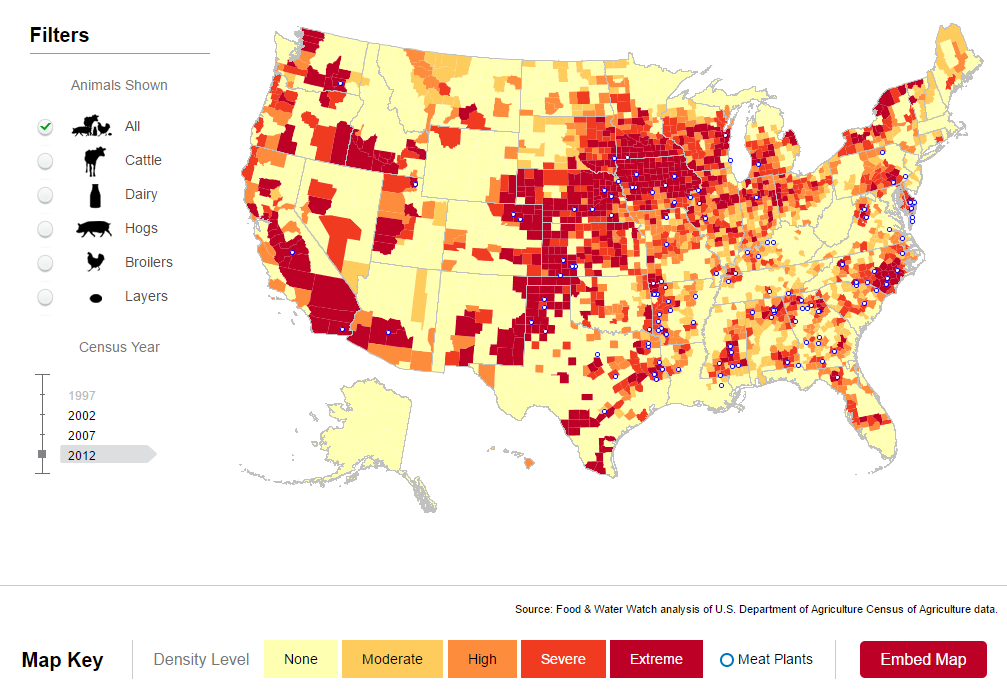

Even over a decade ago, the scale of the challenge was substantial. According to Food & Water Watch, livestock and poultry on the largest factory farms produced an estimated 369 million tons of manure in 2012—almost 13 times more than the waste produced by the U.S. human population at that time.[1] While household waste is typically treated through municipal sewer systems, most factory farm manure is stored in lagoons and ultimately applied, largely untreated, to farm fields as fertilizer. Globally, roughly one-third of food produced for human consumption is lost or wasted , amounting to on the order of more than a billion tons of food each year, worth around $1 trillion . [2] Without better nutrient management and recovery tools, these waste streams continue to drive water quality and climate challenges.

Nutrient runoff from agriculture has been widely blamed for causing algae blooms in natural water bodies worldwide. These excessive nutrient levels not only fuel algae growth but also impose significant financial burden on drinking water treatment. Moreover, they negatively impact tourism and recreation industry, commercial fishing industry, property values, and pose health risks to humans, pets, and the environment.

As per the Environmental Protection Agency (EPA) :

Photo source: Food &

Water

Watch

Photo source: Food &

Water

Watch

This problem was already substantial over a decade ago. According to an analysis of USDA figures by

Food & Water Watch

,

livestock and poultry on the largest factory farms produced an estimated

369 million tons of manure in 2012—almost 13 times more than the

waste from the entire U.S. human population.

[1]

This 13.8 billion cubic feet of manure is enough to fill the

Dallas Cowboys

stadium

133 times.[2] Household waste produced in most

U.S.

communities

is treated

through municipal sewer systems, but factory farm manure is

stored in lagoons

and

ultimately

applied, untreated, to farm fields as fertilizer (Food &

Water

Watch).

Globally, about one-third of food is wasted: 1.6bn tonnes of

produce per year,

with a value of about $1 trillion. If this wasted food were

stacked in

20-cubic-meter

skips, it would fill 80 million of them, enough to reach all

the

way to the moon

and

encircle it once over[3].

[1] USDA National Agricultural Statistics

Service.

2012 Census of

Agriculture. United States Summary and State Data at Tables

11, 12 and 20; Food & Water Watch calculation comparing

human

and livestock

waste production

based on EPA (2004) at 9.

[2] USDA Natural Resources Conservation Service.

“Agricultural Waste

Management Field Handbook.” Chapter 4, Agricultural

Waste Characteristics. March 2008 at 4-12 to 4-20; Dallas

Cowboys. [Press

release]. “Dallas Cowboys

Stadium Design Statement.” December 12, 2006.

[3] Half of all US food produce is thrown

away.The

Guardian. Jul 2016

Nutrient runoff pollution is devastating freshwaters in the U.S. and worldwide. Stricter regulations on manure and industrial waste management are increasing pressure to contain nitrogen and phosphorus, but scalable solutions are limited. Farmers spend tens of thousands annually on compliance with regulations.

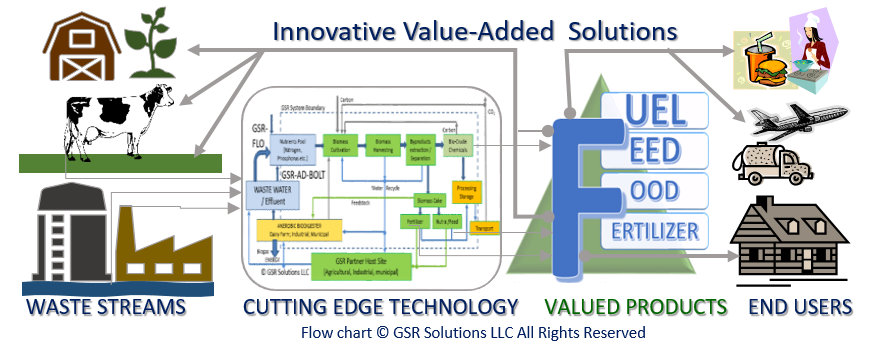

Our patented, scalable platform revolutionizes nutrient management, turning excessive waste nutrients into revenue and savings. By converting waste nitrogen and phosphorus into valuable products, we help agricultural farms and industries save on treatment costs and tap into new markets. Transform waste into profit with our advanced biotechnology and biomass production for food, water, and energy industries. Discover a premier nutrient recovery solution and put it to work at your site.

GSR provides more than technology. Our team supports dairies, anaerobic digester developers and operators, food & beverage processors, municipalities, utilities, and renewable energy project partners through the full life cycle of nutrient recovery projects, from the first assessment through integrated commercial operations.

Have a site, waste stream, or project in mind?

Discuss Your Project with Our Team

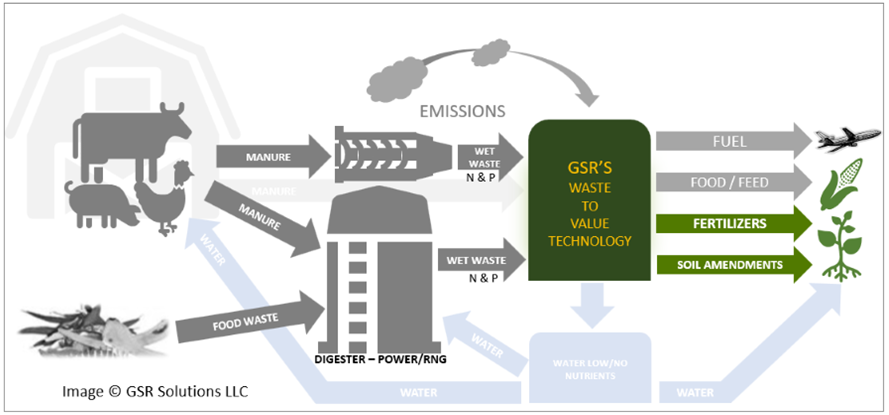

The GSR-AD-BOLTTM system is designed for anaerobic digester operations at animal farms, food and beverage industries, breweries, and municipal wastewater treatment facilities. This system efficiently converts waste nutrients, nitrogen, and phosphorus in liquid digestate effluent into valuable products, effectively preventing water pollution.

Common anaerobic biodigester systems used for Combined Heat & Power (CHP) or Renewable Natural Gas (RNG) production generate high nutrient liquid digestate effluent that needs to be managed as per regulations. These systems are effective primarily in treating biochemical oxygen demand (BOD), which measures the level of organic pollution in water. However, these systems do not effectively manage nutrients like nitrogen and phosphorus. The effluent from biodigesters requires further treatment to meet water quality regulations before it can be recycled on a farm or discharged into water bodies. Many operations lack the capability to manage this additional treatment process. GSR-AD-BOLTTM changes the nutrient management game.

GSR-AD-BOLTTM system uses a proprietary biological process to efficiently recover nitrogen and phosphorus from digested effluent in controlled stages. It further reduces the BOD of anaerobically treated effluent. GSR-AD-BOLTTM process enables the production of valuable byproducts such as organic fertilizers, fuel, and cleaner water. By enhancing the economic and environmental performance of digesters, our system has demonstrated success in projects utilizing dairy and industrial effluents, with the support of our partners.

Over the past several years, we have collaborated with dairy farms experienced in operating anaerobic digesters for generating electricity. Additionally, we are engaging with farms interested in installing new digesters. The GSR-AD-BOLTTM systems are the crucial pieces of the puzzle that complete these systems, enhancing efficiency and sustainability.

1

5

15

Explore our case studies to see examples of our completed projects.

Here is one featuring a GSR-AD-BOLTTM system integrated with a large dairy farm operating an anaerobic digester. In 2023, USDA NRCS Hub Co-leads from ten different USDA offices, along with other USDA leaders from across the country, visited this dairy farm site to observe the biodigester with GSR-AD-BOLTTM system and its products (image below). The nutrient recovery samples are displayed on the digester top, set against the backdrop of the cow barn that supplies dairy manure for the digester, and an organic fertilizer booth display (images below).

During the tour, the USDA team saw the farm's biodigester, and the commercial production of organic fertilizer supported by the GSR-AD-BOLTTM system that captures nutrients from the liquid manure digestate. The cow bedding produced is transferred to the barn to ensure the cows are well-bedded, which when spent goes back into the digester along with manure generated used for electricity production, nutrient recovery for organic fertilzier production. And the cycle goes on.

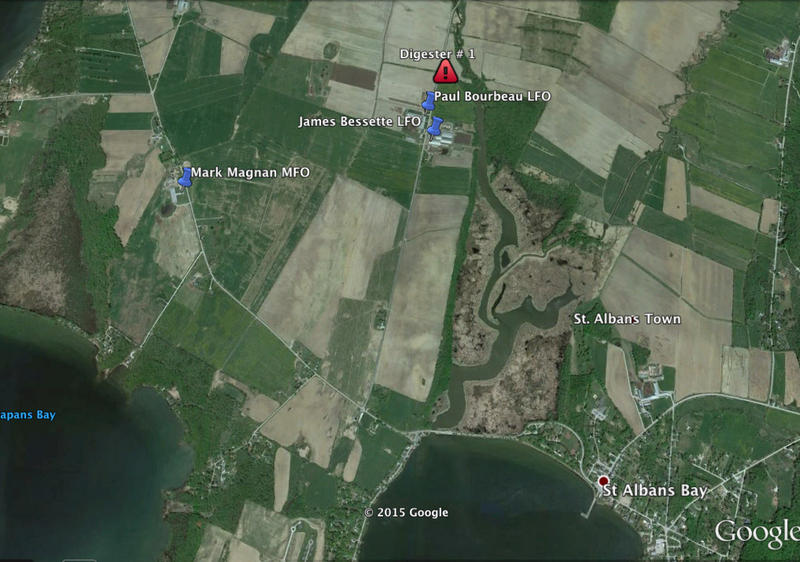

Here is another example: one of the five pilot projects undertaken by a mid-sized dairy farm prior to the pandemic. Two other projects are in progress.

Photo source: Google Maps

Photo source: Google Maps

Here's a different example beyond single-family farms. This project was undertaken by GSR's partner utility, with planning completed in 2018. A new similar feasibility project involving multiple farms began in 2022 and is currently in progress.

Photo

source: Green

Mountain Power Google Map in VPR News

Photo

source: Green

Mountain Power Google Map in VPR News

The GSR FLOTM system is designed to recover nutrients at the non-digester animal farm and industry operations, requiring essential waste nutrient management solutions. The GSR FLOTM system efficiently recovers nitrogen and phosphorus, significantly reduces the BOD of waste effluent, and produces valuable byproducts like fertilizer and fuel, as demonstrated in our projects with dairy and industrial effluents.

Potential sites for the GSR FLOTM system include dairy farms, food and beverage industries, breweries, and municipalities treating wastewater. These locations benefit significantly from this system, which recovers nutrients without requiring anaerobic digestion. Dairy farms can manage manure and food waste more effectively, while food and beverage industries, including breweries, can handle their wastewater more efficiently. Municipalities also gain from improved nutrient recovery and waste management processes.

Explore our case studies to see examples of our completed projects. These include dairy farms managing manure and food waste, as well as breweries handling wastewater.

3

2

3

15

The expansion of most family farms and food and beverage industries is often constrained by waste nutrient management challenge, which is crucial for achieving economies of scale. The GSR-FLO TM system offers a solution, enabling these operations to manage waste nutrients more efficiently and thus providing the opportunity for growth and expansion.

GSR-BCTM System

The GSR-BCTM system is specifically designed for industries with unique waste nutrient management needs, transforming their byproducts into valuable new products. For instance, in biochar production operations, it treats waste streams and utilizes biochar produced from various types of biomass, such as wood, crop residues, yard waste, food waste, animal manure, and municipal waste. Biochar is created through the thermal decomposition of biomass via pyrolysis or gasification, with gaseous and liquid byproducts used to produce biofuel. GSR leverages biochar and similar materials to enhance soil health and produce a range of agricultural products.

Many animal farms, food & beverage industries, and other operations generate liquid waste rich in nitrogen and phosphorus. While anaerobic biodigesters can reduce organic load, measured as biochemical oxygen demand (BOD), which is the amount of oxygen needed by microorganisms to break down organic waste in water, as they are not effective at removing these excess nutrients. As a result, untreated effluents cannot be safely reused on farms or discharged into waterways without further treatment to meet water quality regulations. GSR’s proprietary biological process is designed to close this gap.

GSR’s waste to value process uses proprietary biological technology to modify the properties of incoming waste streams, with the goal of removing excess nutrients and improving water quality. Following pre-treatment, the system employs advanced microbial-based biomass to remove nitrogen and phosphorus from wastewater, producing a cleaner water output. After treatment, the solid fraction is separated and converted into target molecules and products, while the treated water is recycled for reuse. In certain variations, additional biogenic materials such as biochar or plant-derived materials are incorporated to further enhance treatment efficiency.

GSR's patented, scalable, bolt-on platform changes the bioenergy production game - it converts the rapidly growing problem of excessive nutrients into an enormous opportunity by generating new revenue sources from recovered nutrients and saving on treatment costs both nationwide and worldwide. GSR's process combines cutting edge technological advances with mass production of the fastest growing biomass feeding on excess nutrients to convert waste into valued products for the fastest bioenergy markets.

Food & beverage Industries and Livestock farms generating wastes and effluents containing excessive nutrients are our potential partners. They are required to meet standards for the handling and recycling of wastewater nutrients per guidelines from state and federal regulatory agencies.

GSR-AD-EE2TM are unique anaerobic digesters (AD) with enhanced economic and environmental (EE2) performance for generating biogas-based products (e.g., RNG, CHP, cow bedding), and converting digestate into valued products (e.g., biogas, fuel, fertilizer, and feed). GSR has been developing its digester arm for offering these as well as other digester options.

Project sites: 1) Multiple dairy farm projects in planning phase

The GSR-AD-EE2-OILTM system facilitates production of alternative liquid fuel including jet fuel and biodiesel for transportation and heating. These systems work with anaerobic digesters as well as bolt on to non-AD operations. This system is one of GSR’s projects that was one of the three national Farm to Fly F2F2 initiatives supported by the US Department of Agriculture (USDA), the Department of Energy, and Commercial Aviation Alternative Fuel Initiative (CAAFI).

Project sites: GSR Farm-to-Fly Phase-1 project completed in 2018, and Phase-2 is currently under planning.

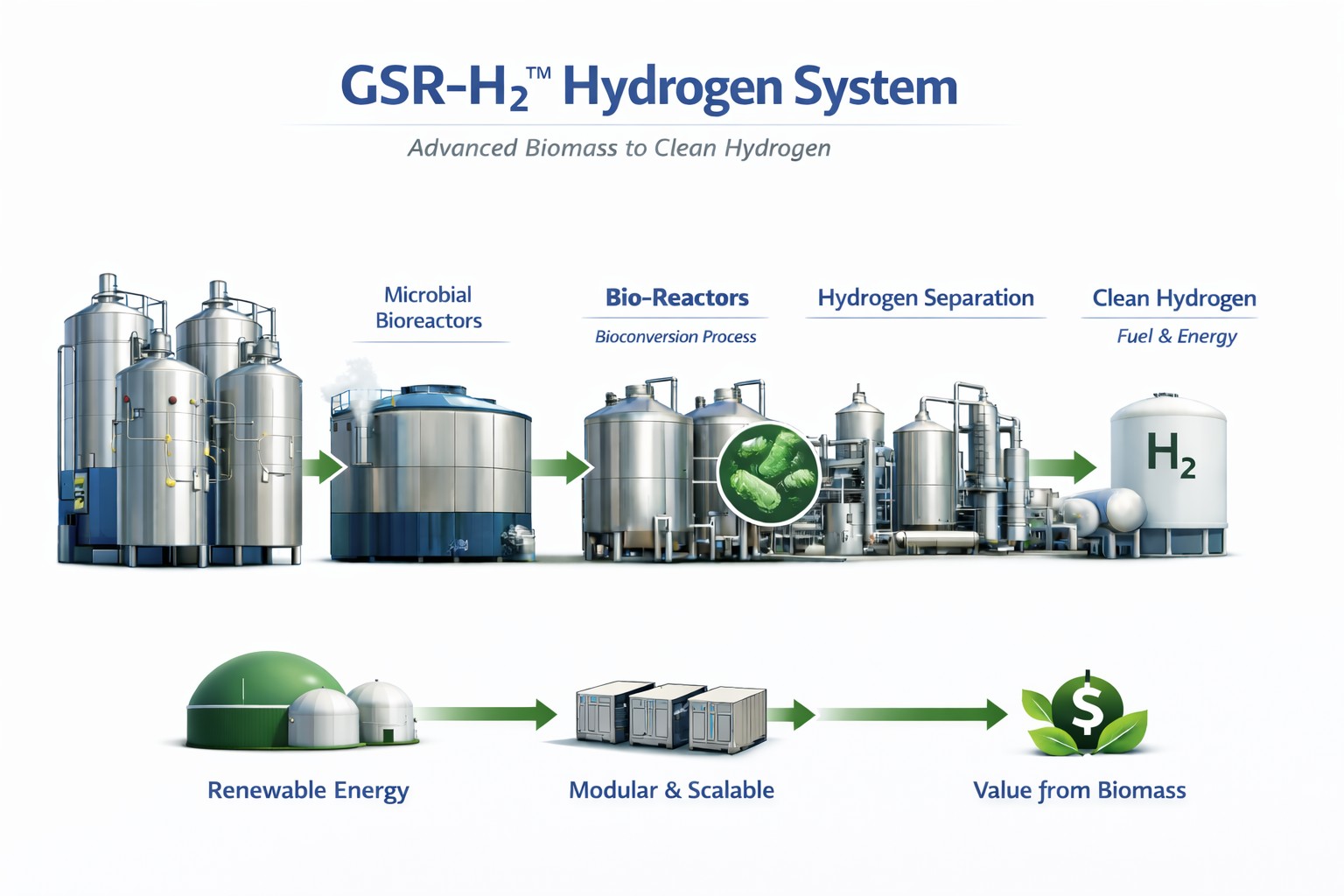

The GSR-H2TM Hydrogen System converts advanced biomass into clean hydrogen using an integrated bio-conversion process. Our system cultivates feedstock on-site and routes the biomass through optimized conversion steps to generate hydrogen gas, with modular equipment designed for reliable operation and straightforward integration into existing water, waste, or renewable energy infrastructure. The result is a scalable pathway to low-carbon hydrogen while unlocking additional value from biomass streams.

Project sites: GSR-H2TM planning was completed prior to the pandemic, and subsequent the phase is currently underway.

Have a project, site, waste stream, or project in mind?

Discuss Your Project with Our Team

GSR offers unique solutions to rethink how energy systems are designed and operated, to maximize the economic and environmental performance of these systems, and to convert unmanageable waste nutrient effluents from digesters into many high-value marketable products, inlcuidng renewable jet fuel / SAF / hydrogen and other products.